In prep for having a synthetic stucco specialist come out and coat/seal/protect the edges of the cutouts and ends of the augments, we got a couple handy men out to pull the spray blocks off from the shotcrete spraying.

I also had them tap off the concrete that had stuck to all the rebar that is sticking out to tie in the vertical flat walls/soffits.

I will have them start constructing the Window/Door Bucks while we are waiting to get the Vero Panels finalized and ordered.

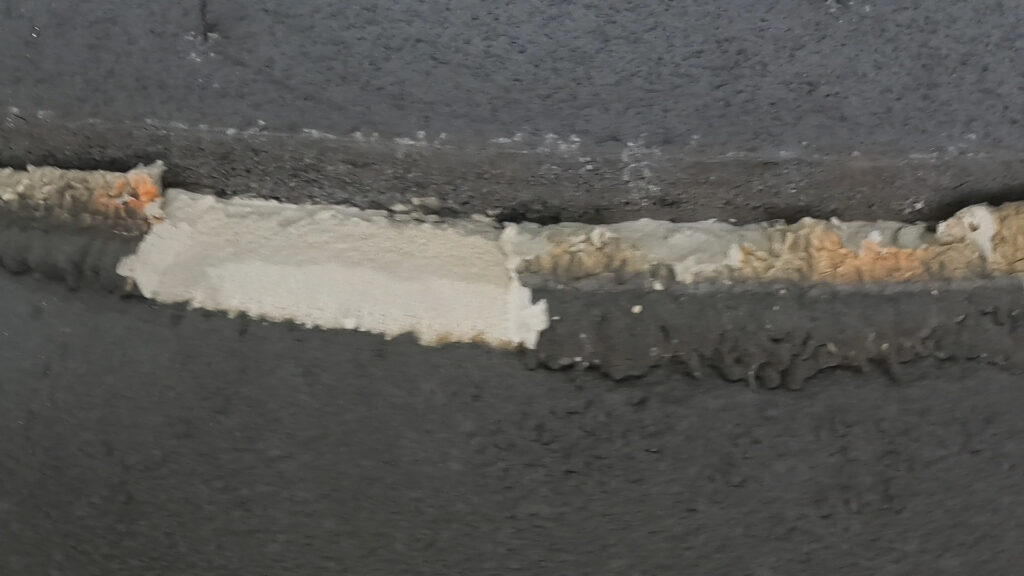

Here are pictures from after they finished pulling out the spray blocks.

I realize many of these pictures may be sort of difficult to understand what you are seeing. It is the edge of the concrete that had a wood spray block to make for a cleaner edge after spraying. Next step here is the EIFS or Synthetic Stucco contractor will come along and cut the foam/airform back to even with the concrete and then coat it with the primer coating that sticks to everything to make sure the edge of the airform doesn’t peal away from the foam and that the foam edge gets protected from UV degradation and damage. We want to make sure the foam is sealed and protected to keep vapor drive from filling it with water vapor. See Polyurethane foam won’t absorb liquid water but water vapor can be driven into the foam which can saturate it if you trap moisture between the airform and the foam and then have the sun heat it up, it can cause blisters between the foam and the airform as well as saturate foam with the water vapor being driven into it. High priority right now is to protect the connection point at the airform/foam and concrete. The reason we didn’t immediately cut the openings all the way open was we needed to get a contractor here to handle sealing and coating the edges before we expose them.