This is from Day 2 of Foaming. We have had lots of rain/humidity which has impeded foaming since moisture getting into the layers of foam cause problems. This is NOT the best time of year to be spraying polyurethane foam in Florida. In fact, it is probably just about the worst time of year to be doing it. About the only thing that would make it worse is if there were a hurricane bearing down on us. “knock on wood”

There was actually a near disaster yesterday when the inflation fan overheated and shut down. Luckily they already had a good layer of foam over the whole dome and it stood even with the loss of air pressure. It wasn’t a thick enough layer over everything to provide much margin for safety or comfort but it did stand the loss of pressure while the guys scrambled to get the backup fan going. We might need to set up sun protection for the fans.

They will soon be installing the spray stops (or Bucks) for the cut out openings but they decided it would be better for safety/support to go ahead and at least get a couple inches of foam over the big cut out openings for support in case of power fail or fan fail since 2-3 inches of foam will be self supporting in a dome this size.

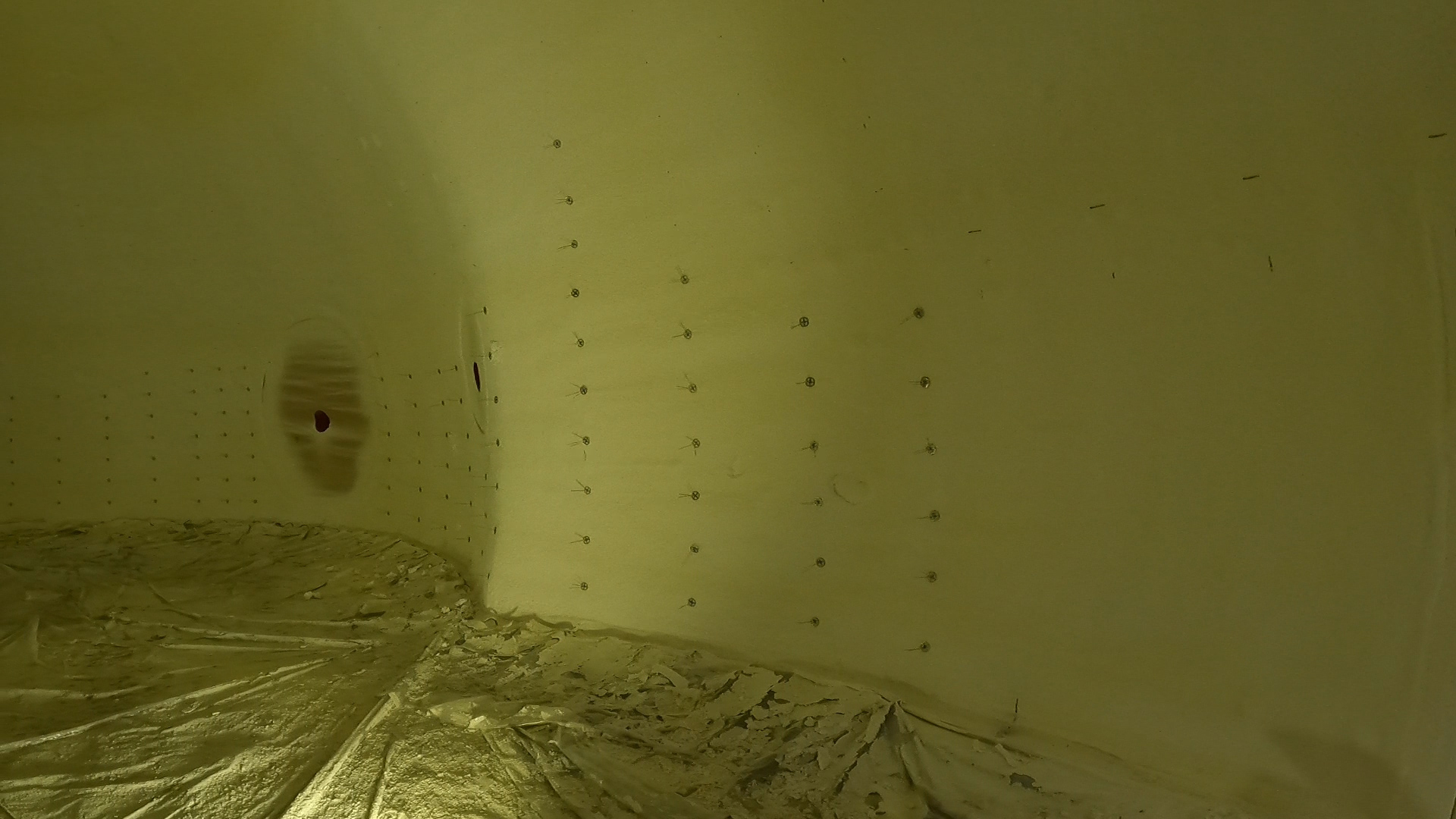

The spots you see all over the place are the rebar stickers. Basically little metal pieces that stick into the foam with some wires sticking out to the inside of the dome so that after another layer of foam is applied, they can secure the rebar. After foam is done, First they will do most of the Horizontal rebar and then they will start on the vertical rebar.